IEEE Global Engineering Day is celebrated annually on May 13th. On this day, we acknowledge the remarkable accomplishments of engineers and their significant impact on society. The contributions of engineers have altered the course of humanity and revolutionized our daily lives. From the structures we utilize to the technology we rely on, it takes incredible skill and intellect to create such marvels.

Pen and Paper

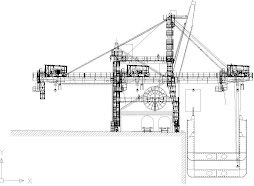

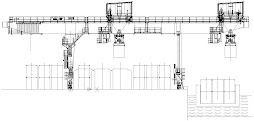

Engineering has traversed a long path to reach where it stands today. The earliest example of engineering drafts dates back to 2000 B.C when an aerial view was captured for a fossilized plan of a Babylonian castle. Fast forward to the 1950s. Engineers during this decade relied on similar equipment used today, but on a much larger scale. Students today also use drawing boards, pencils, erasers, and geometric tools; the main difference is the size of their work surfaces. While students today typically work on standardized paper sizes like A0, A1, or A2, engineers in the 1950s worked on pages as large as the floors they walked on.

Engineers before AutoCAD

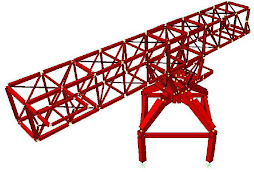

Their work wasn’t confined to set dimensions; it often extended across entire rooms, showcasing the scope of their engineering projects. They did, however, strive to condense all their intricate drawings onto a single sheet of paper, demonstrating their commitment to precision and efficiency within spatial limitations.

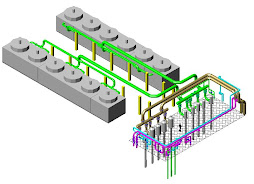

The Inception of AutoCAD

The revolution in engineering drafting commenced in 1963 with the introduction of Sketchpad, a groundbreaking program developed by Ivan Sutherland. Sketchpad marked a pivotal moment in the field as the first graphically interfaced CAD program of its kind, albeit rudimentary by today’s standards. It provided users with the capability to create x-y plots, laying the foundation for modern CAD systems.

Despite the departure of John Walker, the company found new leadership in Carol Bartz, whose tenure further propelled Autodesk’s success. Under her guidance, Autodesk expanded its portfolio, offering a diverse range of software tools tailored for design, modeling, rendering, and applications. Today, Autodesk stands as a powerhouse in the industry, with AutoCAD’s market dominance serving as a testament to its enduring impact on the world of engineering and design.